How Does A Pilz Safety Relay Work

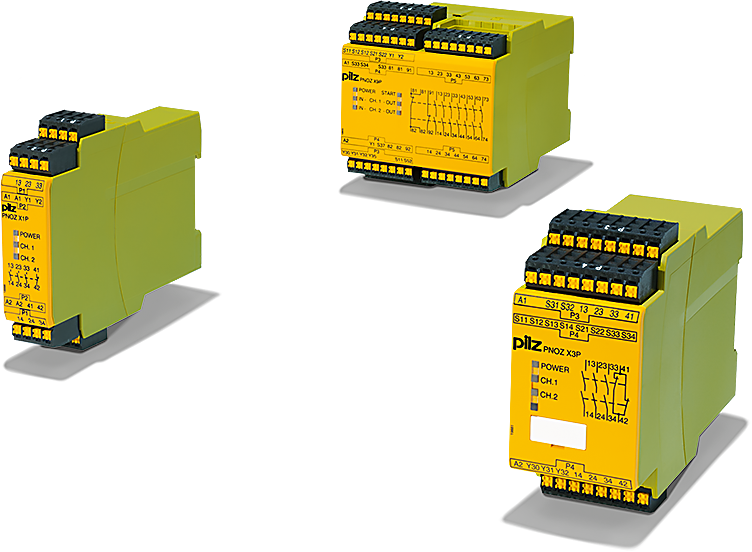

The design technology is the main difference between the safety relays.

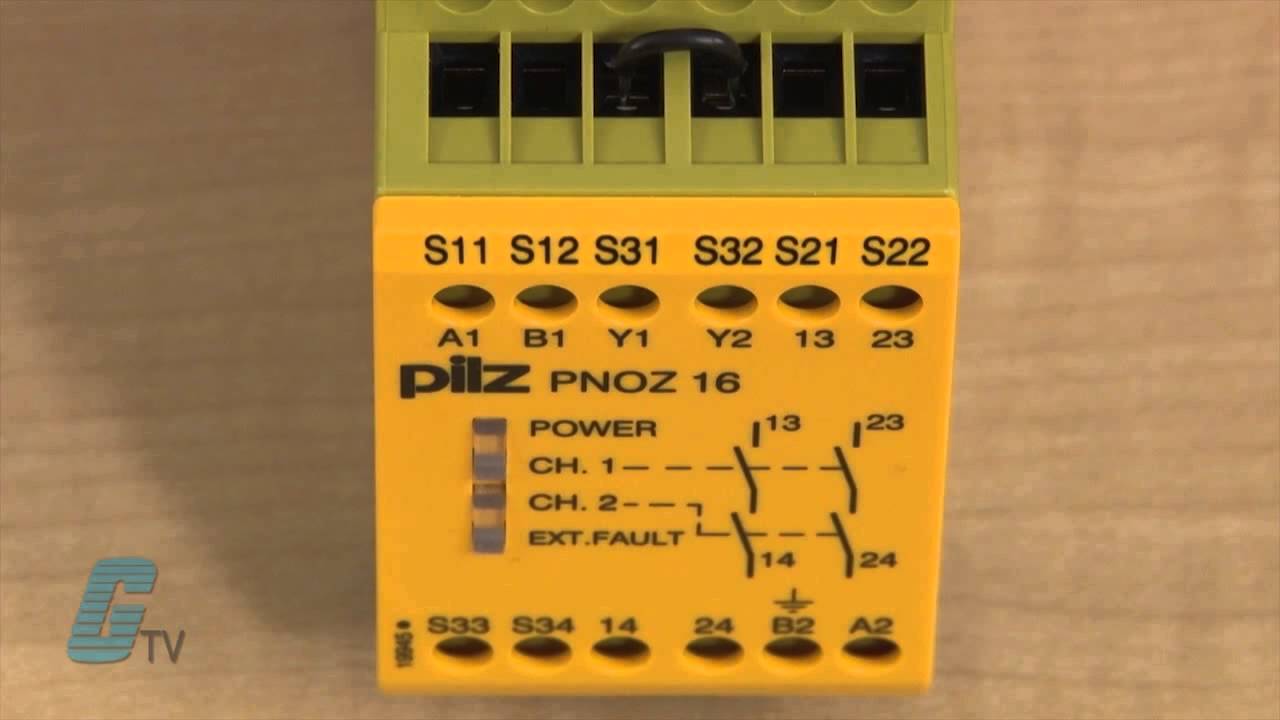

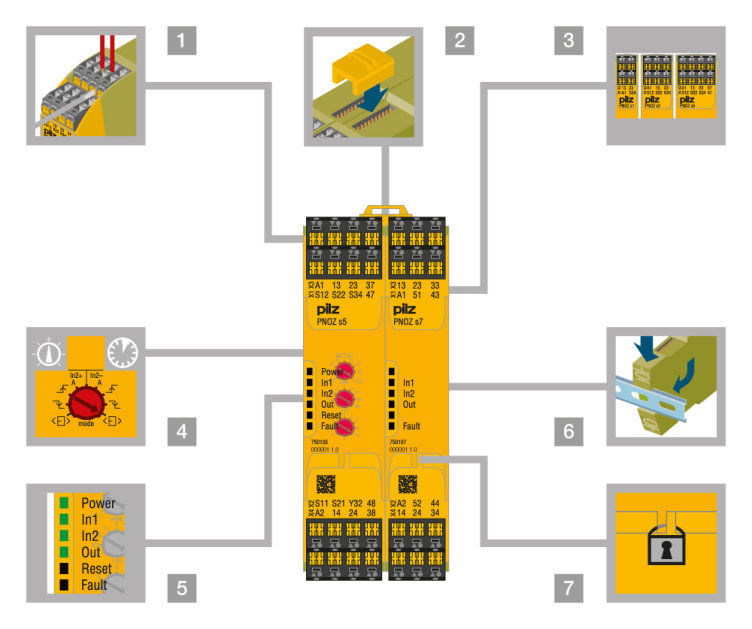

How does a pilz safety relay work. In 1987 pilz patented the first emergency stop relay to protect man and machine. If one relay fails and stays closed the other relay will still open. By measuring flow of current the safety relay checks for welded contact sets and wire breaks. When connected to other safety relays they guarantee full monitoring of a plant or machine.

Timing is the other fault detection method safety relays use. Two relays in series will be turned off together. Pressure sensitive safety relays can be used in conjunction with safety mats to ensure the safety of personnel and further supplement other safety devices. This is all done with timing.

When a fault occurs or a detection zone is violated they initiate a safe reliable response safety relays are encountered in almost every area of mechanical engineering mainly where the number of safety functions is quite manageable. In accordance with safety procedures only one output circuit can be used at a time. Two relays in parallel will be turned on together. They meet the requirements of en 60947 5 1 en 60204 1 and vde 0113 1.

A safety relay detects wire breaks and faulty contactors actuators by sending out electrical pulses through the wiring. Safety relays are used to reduce risk. For example one may setup a set of light curtains to allow objects to pass through it while the safety mat is activated allowing access to load or unload a machine. The safety relays pnoz monitor safety functions such as e stop safety gates light barriers light grids two hand controls pressure sensitive mats speed standstill and much more too every day pnoz safety relays prove themselves in millions of applications worldwide.